In house Fabrication

Fabrication

Expertise at HNL

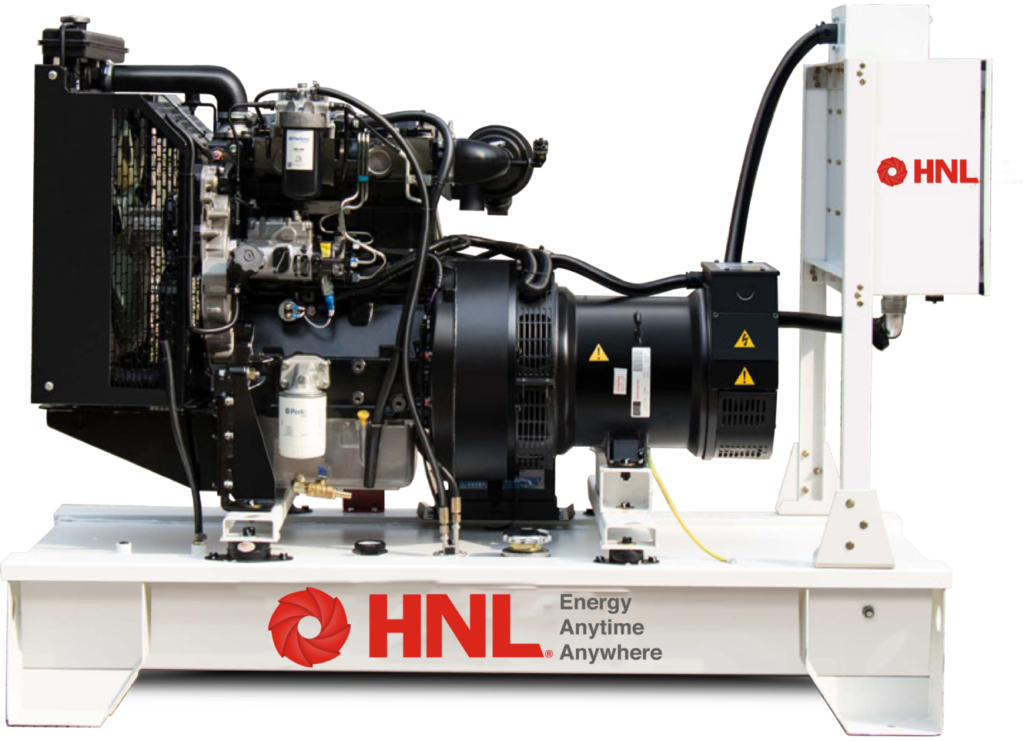

In order to meet the ever-increasing need of fuel storage tanks, sound attenuation and weather resistant enclosures for generators, automatic and manual fuel filling systems along with numerous other metal works related to solar panel installation structures, we here at HNL have a well-established and fully equipped fabrication team. The team is devoted to not only manufacturing standard products but, supervised by our design engineers can provide our clientele a wide variety of customized products.

In House Fabrication

Super Silenced Weather Proof Acoustic Enclosures

Best quality weather resistant & sound attenuation enclosure for outdoor applications. Meeting the highest quality international standards and custom built for domestic, commercial, industrial as well as medical grade usage. Furthermore, our engineers design the enclosures keep in account the requirements of site environmental conditions.

DESIGN:

The enclosure is full steel structure, treated with lead oxide for rust protection and then powder coated or normal painted as per client’s requirement. The requirements of air intake for both cooling and combustion are calculated and optimum sized louvers are designed to meet these requirements. Dust filters along with internal lighting arrangements are also an optionally available design specification. Considering the total static weight of the Power Generators, special lifting hooks are designed in order to facility the loading and unloading via cranes.

SOUND LEVEL:

We have a variety of sound levels available as per client requirements.

- Standard soundproof Enclosures: < 72 dBA

- Super soundproof Enclosures: < 65 dBA

The above values are under free field conditions i.e. 3 to 5 meters clearance on all sides, as walls and buildings will affect all noise levels.

Skid and Base fuel tank for Engine & alternator assembly

HNL designed base fuel tanks are rectangular steel tanks constructed of heavy gauge steel (8, 10 and 12 gauge) and include a reinforced steel box channel for generator support. Full height gussets (subbase only) are provided at generator set mounting holes. The design has been tested extensively under conditions far in excess of normal use to ensure that it can safely support the full weight of the generator set.

Dual wall sub-base tanks are designed with a sealed, separately vented, integral fuel containment basin.

All tanks are pressure washed with an iron phosphate solution and then finished with an acrylic primer and enamel paint. The interior is coated with a solvent-based rust preventative.

Inner and outer (dual wall only) tanks are pressurized at 3 psi and leak checked to ensure integrity of weld seams. These tanks are designed as per the fuel consumption of the generator Prime rating and hold an amount of fuel for a specified number of hours of operation such as 8, 12 or 24 hours but, are customizable to 500 and 100 liters in accordance with telecom requirements. DGDP 30 kVA

Two wheeler and four wheeler trolley for Generators

- Provision of pin type genset permanent stationary pedestals for trolley lifting along with screw jack of suitable capacity.

- Heavy duty Pneumatic tire/RIM suitable capacity (5x brand new tires of a renowned brand).

- Heavy duty MS pipe tube Excel.

- Flat bed according to genset/canopy foot print size.

- Main frame 02 No’s C-channels suitable size.

- Trolley inbuilt tool box.

- Hand brake system back wheal fitted.

- back side yellow and red reflector type lights.

- Back excel leaf spring (patta kamani)

- Tool box at rear side

- one spare wheel at right rear bottom.

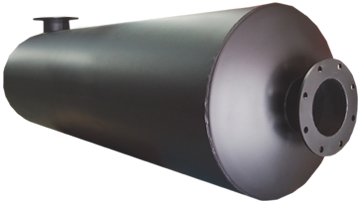

Industrial, residential and hospital grade Mufflers

HNL specializes in the design and manufacture of standard and custom silencers. Our generator silencer portfolio includes a full line of Cylindrical and Rectangular configurations suitable for engines up to 1MW in size handling your most stringent sound attenuation requirements.

- Aluminized Steel, Stainless Steel construction

- Horizontal or vertical mounting brackets and lifting lugs

- Flexible connectors and expansion joints

- Compact modular designs providing ease of installations, less weight and less foot-print

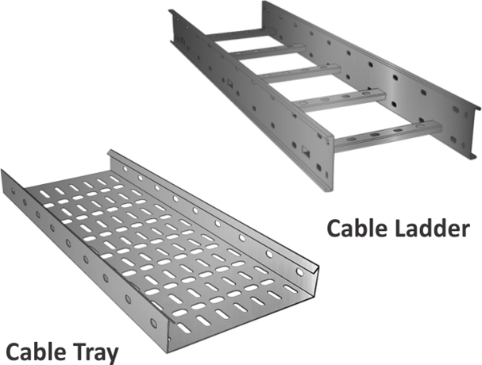

Cable ladders and trays

Cables Trays:

All straight tray sections, angles, offset, corners, cable dropouts, reducers, splice plates, coupling connectors, covers including tray fittings and hardware. Trays shall be fabricated of No. 14 gauge (1.99 mm) minimum thickness steel but are customizable as per clients requirements.

HNL standard Cable trays have the followings specification:

- Bends, both horizontal and vertical, with a minimum center radius of 300 mm / 600 mm, unless otherwise indicated.

- Overall side rail height of 100 mm / 150 mm with a minimum loading depth of 75 mm / 125 mm.

- Tray width 150 mm / 300 mm / 450 mm / 600 mm / 760 mm / 900 mm.

- Brackets with integral tray clamps assembled as a part of the bracket are also provided.

- The assembly is of such a design that one tray clamp is stationary and the other requires the tightening of one bolt only, or its equivalent, in order to securely clamp and position the tray.

Cable Ladder:

Ladder type cable trays consist of minimum 100mm/150 mm deep two longitudinal solid sides with cable supporting transverse members (rungs), spaced at not more than 150 mm/225 mm on center.

All transverse members are rounded edges that will not damage cable insulation and may be used as dropouts without further cable protection.

No portion of the rungs protrude below the bottom plane of the side rails.

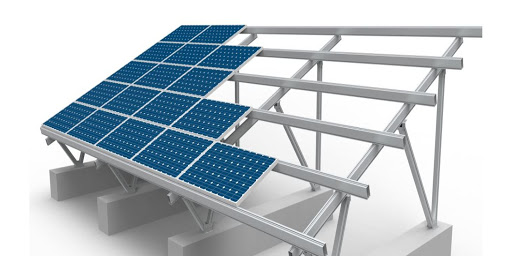

Solar panel installation structures

Hot dip galvanized MS mounting structures for mounting the modules / panels / arrays. Minimum thickness of galvanization is at least 120 microns.

Special Mounting structures are designed to withstand the speed wind speed of 150 kM/ hour. Along with suitable fastening arrangement such as grouting and calming is provided to secure the installation against the specific wind speed.

Before every installation the designs are certified by a recognized Lab/ Institution.

Fuel storage and filling systems

HNL offers a wide range of customised local solution for aboveground as well as underground fuel storage tanks which is suitable for Industrial, power sector, service stations, diesel engine applications etc. Superior strength, performance, durability and reliability is standard for our products. The tanks designed and built as to meet customer‘s specifications.

We specialized in primary ( single wall ) and secondary containment ( double wall ) steel tanks with horizontal / vertical cylindrical or rectangular single wall tanks designed for above ground storage at atmospheric pressure.

- Fabricated, inspected and tested against the leaked tightness before the shipment.

- High quality fitting and superior material of construction.

- Entire range provided with normal and emergency vents openings, sturdy lifting lugs, legs, saddle support and various nozzle openings on the tanks.

- Body of MS steel, painted surface finish Stainless steel with mill finish as standard.

- High grade of welding process to ensure the reliability of each tank.

- (Optional accessories) valves, level gauge, fittings and pipe work along with auto and manual fuel filling systems.

Fuel Tank

HNL offers a wide range of customised local solution for aboveground as well as underground fuel storage tanks which is suitable for Industrial, power sector, service stations, diesel engine applications etc. Superior strength, performance, durability and reliability is standard for our products. The tanks designed and built as to meet customer‘s specifications.

We specialized in primary ( single wall ) and secondary containment ( double wall ) steel tanks with horizontal / vertical cylindrical or rectangular single wall tanks designed for above ground storage at atmospheric pressure.

- Fabricated, inspected and tested against the leaked tightness before the shipment.

- High quality fitting and superior material of construction.

- Entire range provided with normal and emergency vents openings, sturdy lifting lugs, legs, saddle support and various nozzle openings on the tanks

- Body of MS steel, painted surface finish Stainless steel with mill finish as standard.

- High grade of welding process to ensure the reliability of each tank

(Optional accessories) valves, level gauge, fittings and pipe work along with auto and manual fuel filling systems.